【美標(biāo)對夾式止回閥,不銹鋼對夾式止回閥概述】

H71H(W)美標(biāo)對夾式止回閥由閥體、閥瓣、彈簧等組成,水平或垂直安裝于管路系統(tǒng),防止介質(zhì)倒流,具有結(jié)構(gòu)短、體積小、重量輕;

閥瓣關(guān)閉快速,水錘壓力小;流道通暢,流體阻力小;動作靈敏,密封性能好。

【美標(biāo)對夾式止回閥結(jié)構(gòu)圖】

【美標(biāo)對夾式止回閥,不銹鋼對夾式止回閥號、材料及主要參數(shù)】

配管法蘭 | 公稱壓力 | 常規(guī)產(chǎn)品型號 | ||||||

JB/T 74 | PN1.0MPa | H71H-10C | H71W-10P | H71W-10P8 | H71W-10P3 | H71W-10R | H71W-10R8 | H71W-10R3 |

PN1.6MPa | H71W-16C | H71W-16P | H71W-16P8 | H71W-16P3 | H71W-16R | H71W-16R8 | H71W-16R3 | |

PN2.5MPa | H71W-25 | H71W-25P | H71W-25P8 | H71W-25P3 | H71W-25R | H71W-25R8 | H71W-25R3 | |

PN4.0MPa | H71W-40 | H71W-40P | H71W-40P8 | H71W-40P3 | H71W-40R | H71W-40R8 | H71W-40R3 | |

PN6.3MPa | H71W-63 | H71W-63P | H71W-63P8 | H71W-63P3 | H71W-63R | H71W-63R8 | H71W-63R3 | |

PN10.0MPa | H71W-100 | H71W-100P | H71W-100P8 | H71W-100P3 | H71W-100R | H71W-100R8 | H71W-100R3 | |

PN16.0MPa | H71W-160 | H71W-160P | H71W-160P8 | H71W-160P3 | H71W-160R | H71W-160R8 | H71W-160R3 | |

GB/T 9112 | PN2.0MPa | H71H-20C | — | H71W-20P8 | H71W-20P3 | — | H71W-20R8 | H71W-20R3 |

PN5.0MPa | H71H-50 | — | H71W-50P8 | H71W-50P3 | — | H71W-50R8 | H71W-50R3 | |

PN11.0MPa | H71H-110 | — | H71W-110P8 | H71W-110P3 | — | H71W-110R8 | H71W-110R3 | |

PN15.0MPa | H71H-150 | — | H71W-150P8 | H71W-150P3 | — | H71W-150R8 | H71W-150R3 | |

ANSI B 16.5 | Class150 | H71H-A1C | — | H71W-A1P8 | H71W-A1P3 | — | H71W-A1R8 | H71W-A1R3 |

Class300 | H71H-A3 | — | H71W-A3P8 | H71W-A3P3 | — | H71W-A3R8 | H71W-A3R3 | |

Class600 | H71H-A6 | — | H71W-A6P8 | H71W-A6P3 | — | H71W-A6R8 | H71W-A6R3 | |

Class900 | H71H-A9 | — | H71W-A9P8 | H71W-A9P3 | — | H71W-A9R8 | H71W-A9R3 | |

主 要 | 閥體 | WCB(A105) | ZG1Cr18Ni9Ti | CF8(304) | CF3(304L) | ZG1Cr18Ni12Mo2Ti | CF8M(316) | CF3M(316L) |

閥瓣 | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni9 | 00Cr19Ni10 | 1Cr18Ni12Mo2Ti | 0Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | |

壓圈 | 2Cr13 | 1Cr18Ni9Ti | 0Cr18Ni9 | 00Cr19Ni10 | 1Cr18Ni12Mo2Ti | 0Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | |

彈簧 | 0Cr18Ni9 | 0Cr18Ni9 | 0Cr18Ni9 | 00Cr19Ni10 | 0Cr17Ni12Mo2 | 0Cr17Ni12Mo2 | 00Cr17Ni14Mo2 | |

適 用 | 適用介質(zhì) | 水、蒸汽、油品等 | 腐蝕性介質(zhì) | 強氧化性介質(zhì) | 腐蝕性介質(zhì) | 尿素等腐蝕性介質(zhì) | ||

適用溫度(℃) | -29~425 | -196~540 | -196~425 | -196~540 | -196~455 | |||

注:本表為常規(guī)對夾式止回閥的型號編制、主要零件材料及適用工況,其他要求及其型號編制參見對夾止回閥型號編制方法。 | ||||||||

【美標(biāo)對夾式止回閥主要連接尺寸】

壓力級 | 口徑 | 尺寸(mm) | 重量 | 配管法蘭(供參考) | |||||||||

NPS | DN | L | D | D2 | D3 | D4 | 螺栓孔中心 | 螺栓 | 螺栓直徑d | 螺栓長 | |||

in | mm | ||||||||||||

Class | 1/2 | 15 | 16 | 46 | 15 | 25 | 25 | 0.28 | 60.5 | 4 | 1/2 | M14 | 75 |

3/4 | 20 | 19 | 56 | 19 | 30 | 30 | 0.42 | 70 | 4 | 1/2 | M14 | 90 | |

1 | 25 | 22 | 65 | 24 | 36 | 36 | 0.56 | 79.5 | 4 | 1/2 | M14 | 90 | |

11/4 | 32 | 28 | 74 | 31 | 43 | 43 | 0.75 | 89 | 4 | 1/2 | M14 | 100 | |

11/2 | 40 | 31.5 | 84 | 39 | 52 | 52 | 1.3 | 98.5 | 4 | 1/2 | M14 | 105 | |

2 | 50 | 40 | 103 | 48 | 62 | 62 | 2.1 | 120.5 | 4 | 5/8 | M16 | 125 | |

21/2 | 65 | 46 | 122 | 62 | 75 | 75 | 2.8 | 139.5 | 4 | 5/8 | M16 | 130 | |

3 | 80 | 50 | 135 | 76 | 90 | 90 | 3.6 | 152.5 | 4 | 5/8 | M16 | 135 | |

4 | 100 | 60 | 173 | 95 | 112 | 112 | 4.8 | 190.5 | 8 | 5/8 | M16 | 150 | |

5 | 125 | 90 | 195 | 110 | 125 | 132 | 12 | 216.0 | 8 | 3/4 | M20 | 180 | |

6 | 150 | 106 | 220 | 127 | 150 | 158 | 17 | 241.5 | 8 | 3/4 | M20 | 210 | |

8 | 200 | 140 | 277 | 165 | 200 | 208 | 29 | 298.5 | 8 | 3/4 | M20 | 240 | |

壓力級 | 口徑 | 尺寸(mm) | 重量 | 配管法蘭(供參考) | ||||||||||

NPS | DN | L | D | D2 | D3 | D4 | 螺栓孔中心 | 螺栓 | 螺栓直徑d | 螺栓長 | ||||

in | mm | RF | RJ | |||||||||||

CLass | 1/2 | 15 | 25 | 46 | 15 | 25 | 25 | 0.28 | 60.5 | 4 | 1/2 | M14 | 90 | — |

3/4 | 20 | 31.5 | 56 | 19 | 30 | 30 | 0.42 | 70 | 4 | 1/2 | M14 | 100 | — | |

1 | 25 | 35.5 | 65 | 24 | 36 | 36 | 0.56 | 79.5 | 4 | 1/2 | M14 | 105 | 120 | |

11/4 | 32 | 40 | 74 | 31 | 43 | 43 | 0.75 | 89 | 4 | 1/2 | M14 | 115 | 130 | |

11/2 | 40 | 45 | 84 | 39 | 52 | 52 | 1.3 | 98.5 | 4 | 1/2 | M14 | 120 | 135 | |

2 | 50 | 56 | 103 | 48 | 62 | 62 | 2.1 | 120.5 | 4 | 5/8 | M16 | 140 | 155 | |

21/2 | 65 | 63 | 122 | 62 | 75 | 75 | 2.8 | 139.5 | 4 | 5/8 | M16 | 155 | 170 | |

3 | 80 | 71 | 135 | 76 | 90 | 90 | 3.6 | 152.5 | 4 | 5/8 | M16 | 165 | 180 | |

4 | 100 | 80 | 173 | 95 | 112 | 112 | 4.8 | 190.5 | 8 | 5/8 | M16 | 175 | 190 | |

5 | 125 | 110 | 195 | 110 | 125 | 132 | 12 | 216.0 | 8 | 3/4 | M20 | 210 | 225 | |

6 | 150 | 125 | 220 | 127 | 150 | 158 | 17 | 241.5 | 8 | 3/4 | M20 | 230 | 245 | |

8 | 200 | 160 | 277 | 165 | 200 | 208 | 29 | 298.5 | 8 | 3/4 | M20 | 270 | 285 | |

CLass | 1/2 | 15 | 25 | 52 | 15 | 25 | 25 | 0.3 | 66.5 | 4 | 1/2 | M14 | 95 | 105 |

3/4 | 20 | 31.5 | 65 | 19 | 30 | 30 | 0.46 | 82.5 | 4 | 5/8 | M16 | 110 | 125 | |

1 | 25 | 35.5 | 72 | 24 | 36 | 36 | 0.6 | 89 | 4 | 5/8 | M16 | 115 | 130 | |

11/4 | 32 | 40 | 81 | 31 | 43 | 43 | 0.8 | 98.5 | 4 | 5/8 | M16 | 125 | 140 | |

11/2 | 40 | 45 | 94 | 39 | 52 | 52 | 1.5 | 114.5 | 4 | 3/4 | M20 | 140 | 155 | |

2 | 50 | 56 | 110 | 48 | 62 | 62 | 2.4 | 127.0 | 8 | 5/8 | M16 | 145 | 170 | |

【流體阻力系數(shù)、流量系數(shù)及開啟壓力】

水的當(dāng)量體積流量Vw與實際流體的體積流量V按下式換算: 式中:Vw-水的當(dāng)量體積流量,1/S; ρ-流體密度,kg/m3; V-實際流體的體積流量,1/S。 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

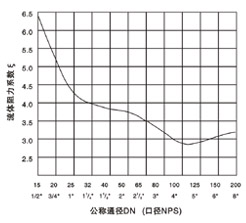

流體力學(xué)性能·H71美標(biāo)對夾式止回閥的流體阻力系數(shù)

【美標(biāo)對夾式止回閥結(jié)構(gòu)特點】 1、結(jié)構(gòu)長度短,其結(jié)構(gòu)長度只有傳統(tǒng)法蘭止回閥的1/4~1/8 2、體積小、重量輕、其重量只有傳統(tǒng)法蘭止回閥的1/4~1/20 3、閥瓣關(guān)閉快速,水錘壓力小 4、水平管道使用,安裝方便 5、流道通暢、流體阻力小 6、動作靈敏、密封性能好 7、閥瓣行程短、關(guān)閥沖擊力小 8、整體結(jié)構(gòu)、簡單緊湊、造型美觀 9、使用壽命長、可靠性高 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

在幾十年的實踐運營中,公司始終堅持以“積極進(jìn)取、保證質(zhì)理、信譽*、用戶*”的經(jīng)營理念,以用戶滿意為Z終目標(biāo)。已形成了整套*的生產(chǎn)、經(jīng)營管理體系,培養(yǎng)了一批高素質(zhì),高水平,經(jīng)驗豐富的專業(yè)工程技術(shù)人員。產(chǎn)品設(shè)計日臻完善,工藝水平不斷提高,與*水平同步行;公司采用CAD計算機輔助系統(tǒng),吸收并優(yōu)化美國W-K-M、日本JSW公司技術(shù),結(jié)合一整套現(xiàn)代化的檢測設(shè)備,嚴(yán)格執(zhí)行《產(chǎn)品質(zhì)量法》和(挪威)DNVISO9001國標(biāo)質(zhì)量標(biāo)準(zhǔn)體系,開發(fā)的產(chǎn)品多次獲得國家和閥門行業(yè)質(zhì)量信得過企業(yè);國家特種設(shè)備制造許可(TS)和CE認(rèn)證已通過審核。

在幾十年的實踐運營中,公司始終堅持以“積極進(jìn)取、保證質(zhì)理、信譽*、用戶*”的經(jīng)營理念,以用戶滿意為Z終目標(biāo)。已形成了整套*的生產(chǎn)、經(jīng)營管理體系,培養(yǎng)了一批高素質(zhì),高水平,經(jīng)驗豐富的專業(yè)工程技術(shù)人員。產(chǎn)品設(shè)計日臻完善,工藝水平不斷提高,與*水平同步行;公司采用CAD計算機輔助系統(tǒng),吸收并優(yōu)化美國W-K-M、日本JSW公司技術(shù),結(jié)合一整套現(xiàn)代化的檢測設(shè)備,嚴(yán)格執(zhí)行《產(chǎn)品質(zhì)量法》和(挪威)DNVISO9001國標(biāo)質(zhì)量標(biāo)準(zhǔn)體系,開發(fā)的產(chǎn)品多次獲得國家和閥門行業(yè)質(zhì)量信得過企業(yè);國家特種設(shè)備制造許可(TS)和CE認(rèn)證已通過審核。